Tank protection is developed based on information about anti-tank weapons of the potential enemy, physics of interaction between those weapons and a tank's armour, and the conditions in which tanks are used and that they fight in. An analysis of anti-tank weapons is a necessary step towards designing tank armour. In the 1950s it became clear that further improvement of tank protection simply through improving the characteristics of steel alloys is impossible. This was primarily true when protecting the tanks from HEAT warheads. The idea to use fillers to protect from HEAT ammunition appeared during the Great Patriotic War, but was not developed until after its conclusion.

Work to improve anti-HEAT protection of both tanks already in production and those just being developed began in the 1950s. New conceptual ideas of active armour were also developed, but the fastest and less risky solution was the development of composite armour that could protect the tank from the most common HEAT warheads used by the potential enemy.

|

| Hull of Object 432, draft project, 1960. |

The idea to use ceramics as protection from HEAT warheads came about in the mid-1950s at the FTI (modern day A.F. Ioffe Physical-Technical Institute). Studies showed that the penetration of HEAT jets into high hardness ceramics was about the same as into armour steel, even though its density was much less. In 1958 FTI and VNII-100 specialists reviewed various uses for anti-HEAT armour research. This was the start of research into anti-HEAT armour with a ceramic filler. The work was done in VNII-100. V.S. Starovoytov directed the work.

Trial and error

There was no ready solution for the issues that the designers of armour for what would be the T-64 tank were solving anywhere in the world. Every problem had to be solved on their own, which resulted in a process of trial and error. Issues arose with protection of both the turret and the hull that required time and effort to solve. The situation was also exacerbated by internal competition, which will be discussed in more detail below.

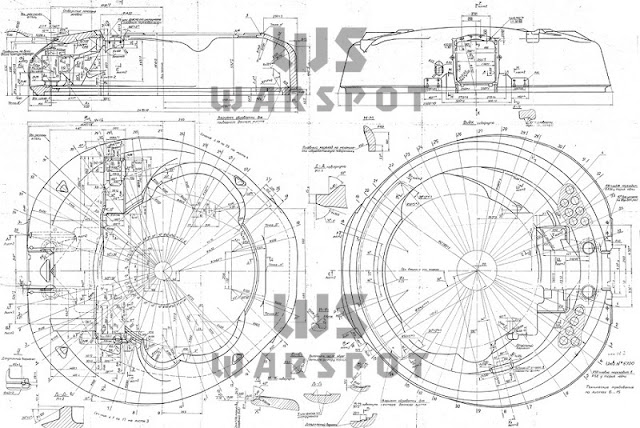

|

| Turret of Object 432 compared with Object 430, draft project, 1960. This drawing shows one of the transitional designs where composite armour was not yet used. |

A technical project prepared in April of 1961 shows a two-layer hull armour: 80 mm of steel plus 140 mm of composite epoxy material (CEM). This design was derived from the Object 432 design developed in 1960. Like on the Object 430, the upper front armour was composed of three parts: the center and the side "cheeks". This was a traditional solution for protection against AP and APCR ammunition, but it turned out to be unsuitable for composite armour.

The two-layer armour (80 mm steel plus 140 mm CEM) that was initially proposed for the T-64 was replaced with a design that had a 20 mm thick steel backing plate and 105 mm thick CEM layer. This layout (80 mm steel plus 105 mm CEM plus 20 mm steel) was chosen as the main type of armour for the T-64, T-64A, and their successors: T-72 and

T-80.

The technical project of the Object 432 developed in 1961 was the first tank in the world to include composite armour for the tank and hull.

Two variants of filler were considered:

- Cast steel armour with ultraporcelain inserts with 420 mm basis and 450 mm equivalent protection against HEAT.

- Cast turret with a steel frame, aluminium anti-HEAT layer (poured after the initial casting), external steel armour, and aluminium layer. The total maximum thickness of this turret would be 500 mm offering 460 mm equivalent protection against HEAT.

Both variants of the turret saved more than a ton of weight compared to an equivalent steel turret.

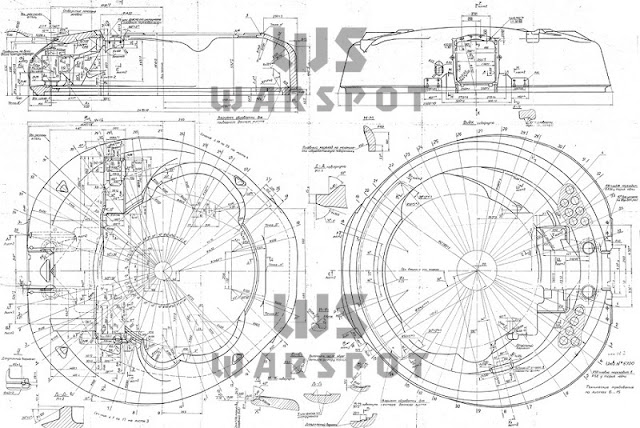

|

| Turret with cylindrical ultraporcelain inserts, Object 432 technical project, 1961. This idea was considered again in 1968, but the final variant used KVP-98 corundum spheres developed by the Slavyansk ceramics factory. It took 12 years of development before the turret was accepted into service in 1973. |

Mass produced T-64 tanks used the turret with aluminium filler, although the turret expanded by more than 100 mm compared to the technical project. The weight also increased. The space inside the turret decreased, and the turret also covered up the driver's hatch at certain angles of traverse.

At the time, the turret had unprecedented protection from shells and HEAT warheads, but also had satisfactory tenacity. This was a great technical achievement for its time, but designers continued to work on correcting some of its aforementioned drawbacks, chiefly to do with the frontal armour bulge.

|

| Production T-64 turret with aluminium filler. |

|

| Production T-64 turret with aluminium filler, cutaway. The turret guaranteed protection from 85 mm and 100 mm HEAT shells (equivalent to NATO 105 mm HEAT shells) and 100 mm flat-tipped AP at angles up to +/- 35 degrees. |

A search for new solutions began. The book NII Stali - 60 let v sfere zaschity covering the development of the NII Stali (Steel Scientific Research Institute) describes this period as follows:

"We had the task of correcting this drawback without increasing the distance between the turret rotation axis and the center of the hatch. The front of the turret therefore had to be reduced by almost 200 mm compared to the "steel-aluminium-steel" turret (from 600 to 410 mm). The decision to reduce the thickness of the turret armour while maintaining its resistance to shells was proposed by V.V. Ierusalimskiy. He proposed doing this by using high hardness steel inserts hardened with the differential isothermic process. This would give a very hard core and a comparatively softer and more flexible outer surface.

The result was quite decent, better than the experimental turrets with ceramic balls that VNII Transmash was working on. Their turrets were thicker than the turret with high hardness steel inserts. One drawback of this turret was the insufficient toughness of the weld seam between the retaining plate and foundation of the turret. It could be destroyed with a nonpenetrating hit from APCR shot.

These results led to a decision to begin producing a batch of turrets with high hardness steel inserts after the welds have been strengthened. However, there was an unsolvable issue. The batch of high hardness steel inserts produced for this task had insufficient impact malleability. When hit with shells, the steel inserts resulted in brittle damage and penetration."

|

| T-64 tank with a turret with aluminium filler and an upper front plate with "cheeks". The T-64 was the first mass produced tank with a brand new type of protection that could adequately resist new weapons. Until the appearance of the Object 432, all vehicles had either monolithic or layered armour. |

|

T-64 tank with a turret with aluminium filler and a straight upper front plate, 1967.

Turret wars

The story describes these events in a dry and mundane fashion, but any tank history enthusiast would no doubt want to know what was concealed behind it.

A decision of the 12th Main Directorate of the Ministry of Defense Industry and unit 52682-III (GBTU Scientific-Technical Committee) allowed the Zhdanov Heavy Machinebuilding Factory (ZhZTM) to cast the first 50 turrets with ceramic filler back in 1966. These turrets counted against the regular production quota. Trials of three turrets with filling made of ceramic spheres were conducted in September and November of 1967 at the ZhZTM and unit 68054 (Armoured Vehicle Proving Grounds).

105 shots were made during the trials, including: - 38 shots of the Rapira HEAT-HE shell at stock speed.

- 18 shots with the same shell at increased speed.

- 9 shots of APFSDS from the Molot gun.

- 15 shots of AP from 100 mm guns.

No penetrations were recorded as a result of the trials.

From a letter written by A.A. Morozov: "The aforementioned trials show that the turrets with ball fillers have a resistance to HEAT that oversatisfies the given requirements. There is a possibility to reduce the weight of these turrets. Considering the results of preliminary work with different shapes of ceramic filler, there is further possibility of reducing the weight. Production experience also shows that turrets with ceramic filler are easier to produce, less time consuming, have a shorter production cycle. This was confirmed by organization G-4448 (ZhZTM) in letter #00252, which indicates that Object 434 turrets take about 900 man-hours less to produce than turrets with high hardness inserts.

Also note that this allows the use of a cheaper material that is not considered a strategic resource for filler.

The series of aforementioned advantages of the turrets with ceramic filler allow us to support the recommendation to continue work on improving the design of these turrets and execution of final trials before accepting them into mass production as described in letter #7889 dated December 22nd, 1967.

Due to the current preparations of our factory for producing the Object 434 tank and similar preparations at other factories, we consider it necessary to make a decision regarding the mass produced 434 tank right now.

Considering the aforementioned advantages of turrets with a ceramic filler, we consider it sensible to begin preparing for production at organization G-4448 in parallel with the final changes to the design and trials.

Before putting the turret into production, cast one turret in order to adjust its geometry and perform penetration trials at G-4448 no later than May 15th, 1968.

Given positive results of turret trials and appropriate corrections, begin mass production of the turret. Take two turrets from the first batch for trials at unit G-68054 or at organization G-4448 under the supervision of G-68054.

All necessary corrections as a result of these trials should be introduced into mass production."

|

|

| Cutaway of the turret with ceramic balls. |

It seemed that the question of the T-64A turret that was coming to replace the T-64 in production was decided. In addition to the Malyshev factory, the T-64A was also going to be produced at factories in Nizhniy Tagil, Omsk, Leningrad, and Chelyabinsk. However, NII Stali, the developers of the turret with steel inserts, did not agree with VNII-100 and ZhZTM, the developers of the ceramic balls. A letter from A.T. Larin dated January 18th, 1968, introduced quite a stir among the designers at Kharkov Design Bureau and the Ministry, as it contradicted the results obtained by the developers and the customer.

"As a result of trials conducted in 1967 by organization A-7701 (VNII Transmash), three turrets with an experimental ceramic filler were tested: K22, K23, and K24.

Based on the results of these trials, organization A-3530 in their letter #7852ss dated December 22nd, 1967, proposed to produce a trial batch of turrets with ceramic filler: 5 units for the 434 tank and 50 units for the T-64 tank.

I find it necessary to make the following notes regarding this proposal.

Not a single turret out of K22, K23, and K24 had the weight required by the Chief Designer.

Not a single turret has the required internal volume and turning radius.

This data is absent from report #005105 on the trials of K22, K23, and K24 turrets dated October 20th, 1967.

Measurements taken by unit 68054 show that the turrets are 200 kg overweight (given the height requirements for 548 mm + up to 6 mm as accepted for T-64 and 434 turrets).

The turning radius of K22, K23, and K24 turrets is greater than the requirement by 10-20 mm according to our calculations. This does not permit one to judge the protection and resilience characteristics of turrets with a ceramic filler produced according to the dimensions and weight provided in the blueprints

- Despite the turrets being overweight, their resilience cannot be considered satisfactory. For instance, a hit from a 100 mm AP shell near belts I-II (shot #17) resulted in a 370 mm long tear in the lower section that moved the metal along the crack by 30-40 mm.

This kind of hit would disable the turret entirely.

Damage of this kind on turrets with aluminium filler or with high hardness steel inserts was not observed.

K22 and K23 had tearing and spalling of the outer layer of armour.

For example, after K23 was hit with a 100 mm shell, a chunk 300 by 300 by 120 mm was knocked off the turret. Such damage was not observed even on turrets with aluminium filler.

Trials of the K16/17 turret with ceramic filler at the Pavlograd proving grounds showed very low resilience when hit with 100 mm ammunition with a tungsten carbide penetrator fired from the D-10T gun (see report #28 dated December 25th, 1967). Out of 7 hits to all areas of the turret in the +/- 35 degree range with an impact velocity of 1400-1430 m/s 7 penetrations were made with an exit diameter of 70-80 mm. Penetrations were made in areas where the weight of the cutaway would be equivalent to that of the K23 and K24 turrets.

Penetration trials conducted by us show that protection from this type of armour piercing shot at a velocity of 1400-1450 m/s can be achieved using armour with aluminium filler, fiberglass, and high hardness steel inserts in the thicknesses used on T-64 and 434 hulls and turrets.

New domestic 100 and 122 mm subcaliber shells with a tungsten carbide core are analogous to 105 mm APDS shot used by NATO tanks, the M60A1 and Leopard. In our opinion, protection of the T-64 tank against 105 mm APDS must be achieved at a range up to 1000 m. Calculations and other data show that the British APDS shot penetrates up to 350 mm of rolled medium hardness armour at 1000 m (impact velocity 1360 m/s) at angles of up to 35 degrees. This impact velocity surpasses domestic subcaliber shot of the same type.

Based on the above, organization V-2652 considers the proposal to build 55 turrets with ceramic filler for T-64 and 434 tanks moved forward by the Malyshev factory and organization A-3530 to be premature, as it is not supported by a proportional amount of evidence from trials of similar turrets or samples of armour.

In our opinion, the following is necessary for turrets with ceramic filler:

- Determine whether or not they satisfy the requirement for protection when they meet the size and weight requirements set in the blueprints.

- Determine the level of protection from subcaliber shot with a tungsten carbide core, as when testing turret K16/17 the level of protection was very low.

- Conduct work to improve the resilience of turrets with ceramic filler when hit in the region of belts I-II with 100 mm shot.

The proposal to produce 55 turrets with ceramic filler can only be considered when all of the above issues are resolved with a positive result."

|

| 70 mm ceramic ball filler from a T-64A turret. |

In a response to the letter, A.A. Morozov turned to his deputies: E.A. Morozov and N.I. Veselovskiy. "What is your opinion? R.I. Butov continues to inform us of high performance under fire. ZhZTM says the same. Figure it out and report."

The letter from the NII Stali director resulted in further work on improving the design of the turret. Even without the penetration of the turret by one shell and the drawbacks indicated by VNII Transmash director V.S. Starovoytov, the initial design was far from ideal.

Moving from models to practical trials introduced the following issues:

- Keeping the structure robust and resilient despite the use of highly brittle materials.

- Protect the turret both from HEAT and kinetic penetrators, particularly subcaliber shot with a tungsten carbide core.

- Mass production of composite armour.

- Development of a ceramic filler that needed to match high protection requirements.

|

| Mass produced T-64A turret with a ceramic filler. |

The first practical trials showed that ceramic filler in the form of cylinders or prisms gives the calculated protection from HEAT penetrators, but the resilience of this composite armour was insufficient. It turned out that the rear face of the armour plays a big role in protection not only from HEAT, but also from kinetic penetrators. ZhZTM was sent an encrypted telegram prohibiting them from presenting turrets with ceramic filler for trials until changes had been made to the design.

Latter turrets had changes to set a minimum distance from the inner and outer faces of the turret to the ceramic filler, which resolved the aforementioned drawbacks. The rear face of the turrets were also reinforced from 170 to 200-220 mm. The ceramic balls were spread out more rationally. A.A. Morozov wrote: "When will all this come to an end? Is there a possibility to test another turret? Who will pay for all this?"

|

| Cutaway of the production T-64A turret. |

Letters regarding positive results of trials and the satisfactory performance of the turrets contradicting A.T. Larin's letter continued to arrive at the Chief Designer's office. All of this contradictory information from competing organizations resulted in additional spending of both time and money.

The answer of VNII Transmash director V.S. Starovoytov to A.T. Larin dated February 26th, 1968, was quite harsh:

"We were informed of a letter from director of organization V-2652 comrade A.T. Larin, in which he baselessly lists three drawbacks of Object 434 turrets with a ceramic filler. We have the following to say about this issue:

- The K-23 turret with ceramic filler was produced in accordance with blueprint R.165-2012-10 produced by the Chief Designer and accepted by Military Representative #30 of the Ministry of Defense at the Heavy Machinebuilding factory. K-23 is equivalent in weight to the S-10 turret with steel inserts. The turning radius and height are within the range specified by the blueprint, regarding which there is a note on the measurement diagram.

- The resilience of the turret is quite satisfactory as noted by the trials commission, units 68054 and 52682-III (report of unit 68054 numbered #3438 and letter from unit 52682-6 #K/855668 dated January 12th, 1968).

- Only a different turret was fired upon with tungsten carbide ammunition at Pavlograd, and even then it was fired at from angles greater than 35 degrees.

As it stands, the letter from organization 2652 contains not a single element of truth to it, and its goal is unclear."

Considering that the turret with steel inserts developed at VNII Stali had no fewer issues, the situation with turrets was quite worrying and could result in a failure to meet production quotas. According to the Central Committee of the CPSU and Council of Ministers of the USSR, the Malyshev factory was supposed to produce a trial batch of T-64A tanks in 1968 and begin mass production in 1969. It was decided to produce cast turrets and accept them into service using temporary technical requirements. Additional trials of turret K35 showed that it met the resilience requirements set in VTU-4334-68.

|

| Belt IV of the turret with a ceramic filler. |

A.T. Larin led NII Stali from 1965 to 1974. In 1973, the turret with a ceramic filler was accepted into service on the T-64A tank. Mass production of these turrets for T-64A and T-64B tanks continued for 15 years, until December 27th, 1987, when the last T-64B tank left the assembly plant. Nevertheless, the turret with ceramic filler was not used by other manufacturers. There were two reasons for this:

- T-64A style turrets required new production lines to produce corundum spheres and baskets for installing them into casting molds.

- Processes for obtaining turrets with required resilience and robustness were never developed, as ceramic elements were subjected to changes as a result of being cast in molten steel, even with thermal isolation paste.

No comments:

Post a Comment