The British tank building school was playing catch-up throughout WWII, which is why by 1943 the most common tanks in the British army were American made. Of course, they did not fully satisfy the requirements of the British, but there was no alternative. British tank development had stalled and the tanks they were delivering were at least half a year behind those of leading tank building nations. The British caught up only by the end of the war. The Comet I was still half a step behind the leaders, but the Centurion I that appeared in 1945 was among the front runners. Few could predict that this would be one of the most successful British tanks of all time and its service would last until the 21st century.

A heavier cruiser

British tank development split into two streams: infantry tanks with low mobility but good armour and cruiser tanks with thinner armour, but better mobility. Gradually, cruiser tanks earned a higher priority, especially after experience in North Africa was analyzed. It turns out that armour was not always enough to protect a slow moving infantry tank on the battlefield. At the same time, it was clear that a cruiser tank must have similar characteristics to that of a medium tank. As a result, British cruiser tanks caught up to German medium tanks by 1942 and the Cromwell even surpassed them. The thickness of their armour also grew, although the British were still behind the Germans. There was also a gap in armament. The guns of German tanks and British ones were comparable in 1940, but in 1941 the British fell behind and only caught up by the end of the war.

The appearance of the Panther tank in the summer of 1943 forced the British to review their standards for cruiser tanks.

The issue of improving the firepower of tanks came up very often. Talk of installing the 17-pounder (76 mm) gun began in 1941. However, it was too large for the tanks that existed at the time. A decision was made to develop a new tank on the Cromwell chassis, the Cruiser Tank A30. The first prototype was built in the late summer of 1942. The initial order called for 1150 of these tanks. The A30 was essentially an auxiliary to the Cromwell, or in other words a tank destroyer. The British could have had these tanks in the field quickly, but a traditional desire to up the requirements and branching alternatives slowed it down. What's worse, the tank was too too and its armour was no better than that of the Cromwell. Rival projects (for instance the A40, an A30 with thicker armour) only served to slow down development.

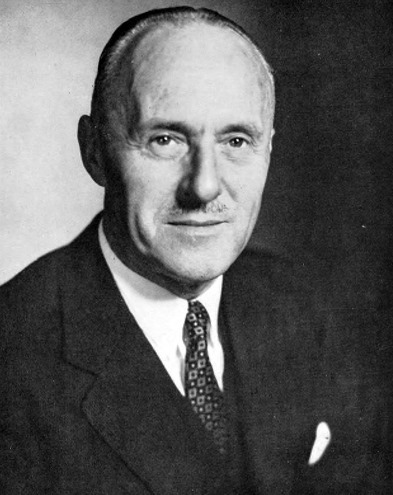

Sir Claude Dixon Gibb, a key figure in the development of the A41 heavy cruiser tank.

The surge of requirements for new cruiser tanks resumed in the summer-fall of 1943. The reason was the appearance of the Panther tank at the Battle of Kursk. A sample only appeared in the UK in 1944 (the Soviets sent a sample), but enough information was available by September of 1943 to cause worry. The tank's armour protection surpassed anything that the British had even on paper. The response was a new burst of projects, including the A44 Heavy Cromwell. The new A34 tank that eventually became the Comet I was classified as a "medium cruiser tank". The development of a "heavy cruiser" was prioritized. Work started on October 8th, 1943, initiated by Major General Raymond Briggs, the head of the RAC as of the summer of 1943. Briggs was an experienced soldier and knew that a cruiser tank needed adequate armour. However, it was not possible to load up an existing chassis more and more. A completely new tank that had nothing to do with the Cromwell was needed.

Engine and transmission of the A41.

The requirements for a heavy cruiser tank as of October of 1943 were as follows. The mass was limited to 40 tons. The armour would protect from the 88 mm gun of the Tiger Ausf.E. Initially this meant 4-5 inches (102-127 mm) of armour in the front hull and 5 inches in the turret. The sides of the hull were 51 mm thick and the sides of the turret were 76 mm thick. The crew was reduced to four men: three in the turret and one driver. Even though the expected power to weight ratio was high (15 hp/ton) the required top speed was just 40 kph. The main armament was either the 17-pounder or its shortened variant, the QF 77 mm used on the Comet. Ammunition capacity had to be at least 75 rounds. Initial requirements called for coaxial two BESA machine guns. They were installed separately from the gun and had the ability to be aimed on their own.

The A41's suspension. Horstmann bogies were used instead of torsion bars.

These requirements did not last for long. It quickly became clear that it would be impossible to meet the 40 ton weight limit imposed by the Bailey Bridge design. The A30 weighed 32-33 tons with much less armour, and the new tank would not fit the requirements. The Panther already weighed 45 tons with less armour. The requirements were altered. The project transformed with the help of Sir Claude Dixon Gibb, the head of the Department of Tank Design as of 1943. The mass was now estimated at 40-45 tons, the requirement for the front armour was dropped to 102 mm with a novel twist: sloped armour. The British finally realized that a vertical front plate was old news (although this didn't stop them from using this concept on the A43 Black Prince).

Another option was added to the two existing guns: a 94 mm howitzer for close support tanks. The requirements for the fighting compartment were also changed. In part, the turret ring diameter had to be increased to 1753 mm, no less than on the Sherman Vc. This allowed the turret crew to work without constraints. To compare, the turret ring diameter of the A30 was just 1695 mm.

The same bogey on the inside. The Germans were also working on a similar suspension at the time.

The DTD created several development groups, each of which worked on their own subject. A group under William Robotham was responsible for the engine and transmission. The designer of the Rolls Royce Meteor engine developed an improved variant named Meteor Mk.IV. The Merrit-Brown Z51R gearbox remained nearly the same as on the Cromwell and Comet, it was only adapted for a heavier tank. The Merrit-Brown turning mechanism also remained the same, but the drive sprockets, final drives, and brakes changed considerably. The suspension developed by AEC also changed. Since it was clear that Christie springs couldn't take any more load, a brand new suspension was developed. A logical decision would have been to use torsion bars, but the British decided otherwise. A suspension was developed based on the design by Sidney Horstmann, first used in Vickers light tanks of the 1930s. The suspension was composed of bogeys with two wheels each and a horizontal coil spring.

The Horstmann suspension was a popular design. The HVSS suspension developed and patented by Harry Knox was a variant of it. The suspension had some drawbacks, but also advantages. It did not take up any space in the hull and the bogeys were easy to replace. The suspension used Newton & Bennett shock absorbers to dampen oscillations. The design was unusual, but turned out to be quite good.

A variety of armament

The requirements for the A41 changed many times from late 1943 to early 1944. This applied to the protection, the armament, and the overall configuration of the hull and turret. It slowly became clear that the short 77 mm gun used on the Comet was not powerful enough to combat new German tanks. It was left on the Comet, but its future with later tanks was in question. There was also an opinion that a more powerful weapon than the BESA should accompany the main gun. Discussions regarding the transmission also continued.

The first experimental Heavy Cruiser Tank A41 in its initial form.

The plurality of opinions on how the tank should look can be seen from the specifications approved by the Tank Department on February 23rd, 1944. A decision was made to build 15 tanks with 17-pounder guns, but 20 mm Polsten guns (a simplified and cheaper Anglo-Polish variant of the Oerlikon) instead of the BESAs. This strange decision was rationalized by the fact that the Polsten gun could be used to fight not only against infantry, but against lightly armoured targets. One BESA machine gun remained in the back of the turret. Five more tanks would be built with a BESA in the front and the back, as well as an SSS Powerflow transmission (the index of these tanks changed to A41S). An 8 hp Morris auxiliary engine was also added to power the electric systems such as the turret fan and traverse motor.

The design of the tank differed from its predecessors significantly. Its designers chose revolution instead of evolution.

While the armament was being finalized, the DTD was working on the hull and turret. This process began in late 1943. The result was conceptually similar to the Comet turret. The turret was mostly welded from rolled armour, but the front was cast. The front armour was 127 mm thick and the sides were 76 mm thick. There was not much here from the Comet, unlike the tank's square turret the A41 had an elongated shape with a large turret bustle. The back of the turret had a round evacuation hatch as well as a rear-facing machine gun.

This tank, like all prototypes numbered 1-10, was equipped with a 20 mm Polsten autocannon.

Unlike the Comet, the commander's station was on the right side, not the left. In addition to the machine gun, a 2 inch bomb thrower was installed in the roof. The gunner moved to the right with the commander and the loader was now on the left. The loader's job was a difficult one: in addition to loading the main gun he also operated the bomb thrower and the Polsten gun.

The same tank after improvements.

While the turret's lineage was clear, the hull had nothing like it in British history. The key wasn't just a sloped front plate. The DTD created a revolutionary design. Even though the front armour was only 76 mm thick (same as the Comet), it was presented at a high angle, giving improved protection. The sides of the hull were also sloped, which helped protect against mines. The engine compartment was also originally laid out. One interesting feature was that the engine deck was composed of multiple sections, which made it easier to open.

Improvements had a significant effect on the turret, largely on the stowage boxes.

The driver's compartment changed significantly as a result of the sloped front plate. The driver looked through two Mk.IV periscopes installed in the two flaps of his hatch. On the march the driver could sit up and look out of the hatch, in this case he could flip up a windshield. Drivers on earlier British tanks could only dream of such comfort. The main ammunition rack was located right next to the driver, behind a bulkhead. A similar solution was used on the T-44 tank. The British didn't know about it, but some solutions appear quite obvious. Unlike Soviet designers, the British did not install any fuel tanks in the fighting compartment or the driver's compartment.

A BESA machine gun was installed instead of the Polsten gun. A triangular marking can be seen behing the machine gun, indicating that the tank is built from mild steel.

Changes in armament continued. A new set of weapons was approved at a meeting held on May 24th, 1944. The first five tanks would have 17-pounder guns, coaxial Polsten gun, and rear facing BESA. The next five would have a hatch instead of the rear machine gun. Five more would have a coaxial BESA machine gun, an evacuation hatch in the rear, but also the possibility of installing a machine gun. The final five tanks had the same machine guns, but a 77 mm gun. This proposal was revised. In the final version, the first 10 tanks had no rear machine gun but had an evacuation hatch and a 17-pounder with a coaxial Polsten gun. Tanks 10-15 had a 17-pounder with a coaxial BESA and no rear machine gun. Tanks 16-18 had both rear machine guns and an evacuation hatch. Tanks 19-20 had coaxial BESA machine guns in the hull. These were likely going to look like the machine gun turret on the "universal" A45 tank.

Third prototype assembled in the spring of 1945. Tanks that were used in Operation Sentry in the summer of 1945 looked like this.

The requirements for armament kept changing as preparations for producing the first 20 prototypes began. Traditionally the work was delegated to civilian subcontractors, but not this time. The Tank Department picked arsenals to build the new tank, including the Royal Arsenal in Woolwich. It would build 10 hulls and 10 turrets, plus two extras. One of the extra sets was built from mild steel and was meant for the first prototype that would be used to test various components. The second extra set was meant for penetration trials. 10 more sets of hulls and turrets would be built at the Royal Arsenal in Nottingham. Various components were ordered from three more arsenals. Rolls Royce and AEC also produced components.

There were few changes compared to the initial tank.

Even though requirements kept changing, this did not slow work down much. Assembly of a mild steel chassis began in the spring of 1944 and trials at the DTD proving grounds in Chobham took place in September. At this point, the tank was codenamed Centurion. This name was initially reserved for the A30, but that tank was named Challenger in the end. The Centurion test chassis was later built up into a full fledged tank, but a triangular marking noting that the tank was built from mild steel was left on the turret. As expected, the tank received a 17-pounder main gun and a 20 mm Polsten autocannon. The prototype was rebuilt several times, and in January of 1945 the Polsten was replaced with a BESA. This tank was the only one of the prototypes to never receive a registration number, but it still carried the designation P.1, marking it as the first prototype.

The front headlights were unusual. There were two of them placed along the center of the upper front plate, one above the other.

Trials of the test chassis were successful. There were some growing pains, but no new tank is without those. However, there was some cause for worry. The new requirements called for a tank that weighed 40-45 tons, but the prototype reached 42 tons before it was fully equipped, plus a tendency to grow was spotted. Nevertheless, successful trials led to a green light for producing a pilot batch of 20 tanks.

A spool of cable replaced the rear machine gun.

A41 prototypes were supposed to receive serial numbers T.352412-T.352417, but in practice the first registration number went to the third prototype and T.352417 was not the highest number. Prototypes built starting in January of 1945 also differed slightly from the mild steel tank. In part, the rear evacuation hatch was altered. Like the improved prototype, these tanks had stowage bins around the turret and spare track links carried on the upper front hull. The headlights of the tank were quite unusual: they were placed vertically, one above the other.

Centurion I armour diagram. Penetration trials showed that the turret sides were too thin and the idea of a split gun and coaxial machine gun was poor.

Even though assembly of the first "real" tank began only in January of 1945, it was finished in April, and five more were finished in May. Woolwich and Nottingham produced three tanks each. Production of the pilot batch dragged on until the end of the summer. The tanks weighed 46.2 tons, but there was room to grow. To compensate, the engine was replaced with the 635 hp Meteor IVA.

An intermediate variant

Even though the war in Europe ended, the six completed A41 tanks did not sit around idle. These tanks were sent to the 22nd Tank Brigade. Tankers with combat experience spent several months getting familiarized with them. A formation within the 6th Guards Division wasn't chosen by accident. It was equipped with Cromwell tanks, so the tankers had a reference point. For the sake of secrecy, this deployment was codenamed "Operation Sentry".

Stowage on a production Centurion. Operation Sentry showed that the correct option was not a 20 mm Polsten gun, but a rigidly linked coaxial machine gun.

The results were made known in late August of 1945. The new tank was a clear success. There were some issues with the gearboxes and engines, but breakdowns were rare. The Centurion proved itself a reliable tank with better mobility than the Cromwell or Comet. There were also negative results. Tankers rejected the coaxial Polsten gun and considered the independently aimed machine gun a bad idea entirely. The variant with a BESA was deemed ideal.

The final look of production stowage.

Further trials showed that there were issues with more than just the coaxial machine gun. The 13th prototype (WD number T.352424) was used in penetration trials. The 75 mm KwK 42 L/70 gun delivered a nasty surprise, the same one as Soviet IS-1 tanks faced in early 1944. Penetrations of the upper front plate were rare, and it was generally considered suitable for resisting the enemy gun. However, there were many instances where the turret was penetrated, both the gun mantlet and the machine gun ball. This meant one thing: the turret armour was insufficient

Production Centurion I diagram.

The solution was simple: improve the turret armour. A turret was produced in the spring of 1945 with a cast sides and a welded in roof. This design was taken as the foundation of the improved turret. The front armour was thickened to 152 mm. The main gun and machine gun shared a mantlet. This variant was named Centurion II and the version with the old turret was renamed Centurion I.

100 production tanks were ordered in the summer of 1945, and it's likely that this number was built.

The question of how many Centurion I tanks were built is an open one. Initially, registration numbers T.351700-T.352199 were reserved for this tank, numbering 500 in all. It is known for sure that a tank received the number T. 351701. It is not known whether or not the order for 100 tanks made in the summer of 1945 was filled or not. Production Centurion I tanks are rarely seen in photographs. The differ from the pilot tanks due to two batteries of smoke grenade launchers (6 per side) on the sides of the turret and some changes in stowage.

A Centurion I loaded to the mass of a Centurion II for trials. The mass of the tank grew to 48 tons due to increased armour.

Only one A41 survives to this day. This is a tank with registration number T.352416 that took part in Operation Sentry. This tank is on display at the Bovington Tank Museum.

Nice article but unfortunately incorrect in some details, which have persisted in books for many years.

ReplyDeleteThe idea of a heavier medium tank for the British army dates back to early 1942: Rolls-Royce had just been given the contract to design a decent tank engine for British tanks - the RR Meteor engine, based on the Merlin aero engine. On seeing what they were being asked to put their lovely new engine into - the Cromwell tank - the RR engineers were aghast, there was so much wrong with the tank design.

The RR engineers immediately proposed a new 45-ton tank, using an uprated 700hp Meteor engine, with the high-velocity 17-Pounder gun - the same spec as the German's were working on for their new Panther tank. A spec, the A29, was written for the new design, and RR called it the 'Clan' tank, after the works building they were using. It looked like an enlarged Cromwell tank, rather boxy.

Sadly, the Government thought the new 45-ton tank too big & heavy, and the project was shelved.

Fast forward to 1943, British Army staff has begun proposing an increase in the firepower and armour of British medium cruiser tanks more vociferously.

The initial specification was for a tank immune frontally to the German 88mm. The new tank had a turret ring big enough to accommodate not only the 17-Pounder gun, but also the 32-Pounder gun that ended up in the Tortoise tank.

The only problem was a 40-ton weight limit that was set for the new design - the designers initially opted for a sloped glacis of only 50mm, loosing not only the hull gunners slot (and weak-point) in the glacis, but also a vision port for the driver in the glacis as well, to ensure maximum armour integrity in the thin plate. The turret got 125mm of armour in a cast & welded design.

Only once the British and Americans captured a number of Panther tanks during the fighting in France in July 1944, did the designers realise the spec needed to be upped - the Panther tank, it was realised, was to be the main tank of the German army - the proposed 77mm gun got dropped, the weight was allowed to go to 45-tonnes, with the glacis upped to 75mm armour, and the turret upped to 150mm armour.