The design of the T-34 tank left a lot of reserves for modernization. The chassis dealt with a 5 ton increase in weight during its production run. A result of a thorough modernization, the T-34-85, entered production in early 1944. This tank received a new turret and an 85 mm gun. The crew increased to 5 people. The T'34's armament was radically improved, but the armour of the Soviet tank remained the same. The T-34-85M tank with improved armour was an attempt to resolve this situation.

Second try at more armour

The idea of improving the T-34's armour surfaced back in the spring of 1941. The T-34 was supposed to receive applique armour to increase the thickness of front armour to 60 mm. The T-34M (a thorough modernization of the T-34) would also have 60 mm of armour. The work that was started in the spring resulted in the creation of two prototypes, but the story didn't end there. On December 25th, 1941, Stalin signed GKO decree #1062ss "On T-34 and T-60 tanks". According to this document, all T-34 tanks were supposed to receive applique plates on the front armour to increase its total thickness to 60 mm as of January 15th, and as of February 15th all T-34 tanks would be produced with 60 mm thick monolithic armour. A few hundred tanks with applique armour were built, but none with thickened base armour. On February 23rd, 1942, Stalin signed GKO decree #1333 that cancelled the applique armour.

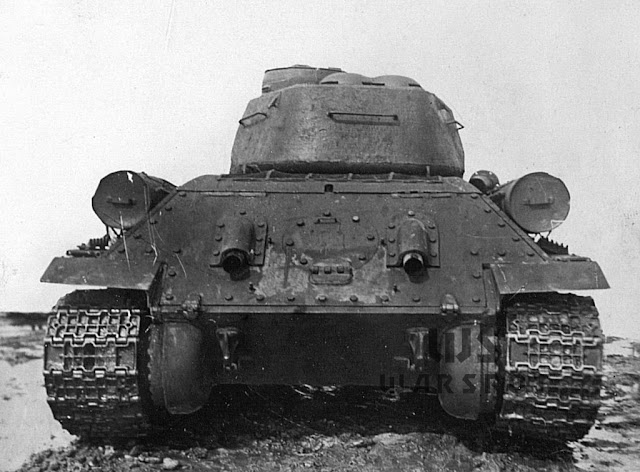

First variant of the T-34-85M, late May 1944. The tank can be identified by the "swollen" DT machine gun cowl and thicker upper front plate.

The idea of improving the T-34's armour was posed many times, but each time the result was negative. In part, this was caused by an increase in the firepower of German anti-tank artillery. The applique armour also affected reliability, and by 1943 the T-34's mass was already north of 30 tons. This resulted in a decreased lifespan of road wheel tires, which was an issue that plagued Soviet designers for many years. However, the GBTU did not forget that the armour had to be improved. Requirements only increased, and by 1943 75 mm of armour was needed to protect against the main anti-tank weapon of the German army: the 75 mm Pak 40. German

Pz.Kpfw.IV tanks and

StuG 40 assault guns also received similar weapons.

This photo was likely taken during trials. The stock drive sprocket with six rollers instead of the experimental smaller one is installed.

The issue of reinforced armour fell in priority temporarily by the fall of 1943. The cause was the must more important issue of improved armament. The first idea was to revive the 57 mm ZIS-4 tank gun (it was even returned to production), although even the ZIS-4 was quickly deemed insufficiently powerful and work on higher penetration 76 and 85 mm guns began.

The 85 mm D-5 gun was chosen. This gun was first used on

KV-85 and

IS-85 heavy tanks as well as the

SU-85 SPG. A mockup of the gun was installed in the turret of the experimental

T-43 tank in early September of 1943. Work on a new turret for the T-34 began later. After successful trials, Stalin signed GKO decree #4776ss "On production of T-34-85 tanks with 85 mm guns at People's Commissariat of Tank Production factory #112" on December 15th, 1943. This was an intermediate tank. The vehicle was equipped with a turret ring widened to 1600 mm and an 85 mm gun, but still had a turret crew of 2. Second, the Central Artillery Design Bureau developed a more successful gun indexed S-53 and accepted into service by GKO decree #4873ss dated January 1st, 1944. These guns were initially supposed to be installed into regular T-34 turrets, but plans changed. Factory #183's KB-520 developed a new 3-seat turret with a 1600 mm turret ring.

GKO decree #5020ss "On increasing production of T-34-85 tanks with 85 mm guns andna widened turret ring" was signed on January 23rd, 1944. Due to some defects found in the design of the S-53 gun, it was improved by factory #92's design bureau (the resulting gun was indexed ZIS-S-53). This gun became the main 85 mm tank gun.

The turret with improved protection had almost no differences compared to the production version.

Stalin raised the idea of improving protection again at a meeting held on December 27th, 1943. The question of the

T-44 tank first came up at this meeting, but Stalin also suggested improving the T-34's hull armour to 60 mm. Malyshev replied that it is impossible to thicken the armour all around due to an excessive increase in mass. However, Stalin's proposal was not forgotten. Keep in mind that it was important to keep the weight down to that of a regular T-34-85. However, 60 mm was no longer enough. The effectiveness of German tank and anti-tank guns had significantly improved by then, and 60 mm was insufficient. It's no surprise that Soviet engineers focused on the Pak 40 when working on improvements to the T-34-85's protection.

The first variant of the T-34-85M did not alter the engine and transmission compartments.

On February 19th, 1944, Malyshev signed NKTP order #109ss. According to the order, a design of a T-34-85 tank with reinforced armour was due on February 25th. This tank would have a 75 mm thick upper front plate and 90 mm thick driver's hatch and machine gun cowl. The front of the turret was 90 mm thick and the sides started at 75 mm and gradually decreased to 52 mm. To compensate, the floor armour was thinner (15 instead of 20 mm), as were the roof armour (15 instead of 20), lower rear plate (30 instead of 45), and turret bustle floor (15 instead of 25). The order also outlined changes to the gearbox gear ratios in order to improve reliability of the transmission. The order requested two tanks: one with the stock hull configuration and one with fuel tanks moved to the rear of the hull. The tanks were due to be built by March 15th, 1944. Factories #112 and #174 would then also built one tank each by March 25th. In case of successful trials, the modernized T-34-85 would go into production.

In the T-44's shadow

The start of work on improving the T-34-85's armour coincided with a whole lot of new work at factory #183. First, factory #183 was putting the T-34-85 into production, which naturally drained a number of engineers. Second, work on the T-44 was in full swing. Unlike the T-34-85 with improved armour, Stalin developed a personal interest in the T-44. It's not surprising that improving the T-34-85's armour had a lesser priority.

The second T-34-85M variant had more changes.

The work lagged behind schedule in this difficult time, but it still carried on. According to factory #183, the development of blueprints finished on February 26th, and they were distributed to factories on March 4th. The first tank variant had a higher priority. Calculations showed that even this variant would weight more than 32 tons. The final drives would remain the same, but the gearbox would be altered. The decision to use old final drives can be explained by a lack of success in developing a replacement. In addition to the improved gearbox, the tank (initially referred to as T-34M) would use smaller 5-roller drive sprockets. To check how the transmission and suspension would react to this weight, a T-34 weighed down to 34 tons was tested.

This photo shows the reduced drive sprockets.

The design of the hull and turret approved by NKTP order #109ss were slightly changed. The factory opted not to reduce the thickness of the lower rear plate to 30 mm, as that would have structural implications. Instead, the final drive covers were thinned down to 30 mm. The turret also underwent a transformation. Factory #183 needed a model first, but it was already overloaded with work on the T-34-85 production turret. Factory staff also had their own opinions about some T-34M components. They wanted to keep the final drive covers at 45 mm and replace the commander's cupola with the superior one from the T-44. There were other ideas, but they all remained on paper.

Installing the fuel tanks in the rear required a number of serious changes.

The significant load on factory #183 as a whole and KB-520 specifically played its role on the T-34-85's development. Neither factory #112 nor #174 ever built a prototype. Even production of tanks at factory #183 lagged behind. The tanks only entered factory trials in May of 1944. Most of the design bureau's suggested design changes were rejected. As order #109ss requested, the lower rear plate was thinned out to 30 mm. The floor and roof were also thinner.

The lower rear plate became taller: 400 mm.

Even though novelties like introducing the T-44's commander's cupola were rejected, the tank indexed T-34-85M still had some changes compared to the initial design. The driver's hatch flap was thickened from 90 to 100 mm. This is likely due to the results of the trials of the T-44 hull prototype. It turned out that a 90 mm thick hatch flap was not enough. As a result, it was decided to make the flap 100 mm thick and increase its slope. This offered reliable protection against the 75 mm Pak 40 gun. Thanks to redistribution of the weight, the T-34-85M first variant weighed only 32,115 kg compared to the production T-34-85 which weighed 32,250 kg. The modernized tank received a 4-speed gearbox with new gear ratios. The drive sprockets were also changed: their diameter was reduced to 520 mm and the number of rollers dropped to 5.

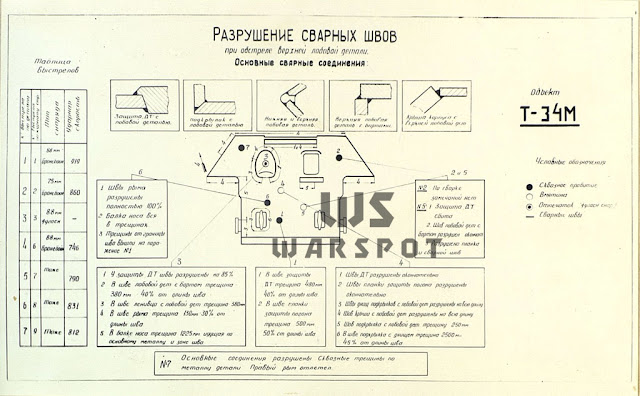

Diagram of the T-34-85M's armour.

The T-34-85M second variant had a great deal more changes. To start, the drive sprocket was also reduced to 530 mm in diameter and had 5 rollers. The deflectors to keep track pins from sliding out were moved to the front of the hull. Finally, the fuel tanks were moved out from the fighting compartment and into the rear. The rear portion of the hull was lengthened and two 190 L fuel tanks were installed for a total fuel capacity of 540 L. Removing the fuel tanks from the fighting compartment freed up room for 4 additional rounds for the ZIS-S-53 gun and 2 machine gun magazines.

Installation of fuel tanks in the rear made servicing the gearbox much more difficult.

The changes made the hull 185 mm longer and increased the mass of the vehicle to 32,230 kg, which was still less than a production T-34-85. The changes to the tank's rear meant that the exhaust system had to be reworked. The lower rear plate was lengthened to 400 mm. To preserve the protection of the fuel tanks, they were covered with 45 mm of armour from the sides. A false pannier floor made from sheet metal was added. The speedometer was also swapped out, but it was incorrect. The linkage to the speedometer was not adjusted to compensate for the smaller diameter of the drive sprocket.

Controversial modernization

The two prototypes were sent to factory trials, and later to the NIBT proving grounds in Kubinka. By the time they arrived there the first variant had travelled for 1205 km, and the second for 1188 km. However, since the speedometer was never adjusted the real results could be different. The proving grounds specialists remarked that the arrived tanks had new drive sprockets, road wheels, and tracks despite their prior usage.

The conditions in which the T-34-85M was tested were far from ideal.

Trials began on May 26th, 1944, even though the trials program was only approved on May 28th. A production tank was also dispatched for comparative trials. Mobility trials lasted until June 10th and showed that the extra armour had nearly no effect on the tanks' mobility. The top and average speeds of the first variant and the production T-34-85 were identical. The second variant was a bit slower, but not due to overloading. Since the engine was never replaced after factory trials, it started suffering from issues, including power loss. The commission took that fact into account, especially since the first variant had equivalent mobility to the production tank. The tanks had to drive in very difficult conditions: on smashed up dirt and forest roads.

Trials showed that the mobility of the T-34-85M was the same as the production T-34-85 tank.

The first T-34-85M travelled for 1006 km during trials, the second 1084 km, and the production tank drove for 1005 km. Even though the mobility characteristics of the T-34-85M remained the same, the new running gear was deemed a bad idea. Trials showed that the smoothness of track engagement was reduced and some instances of the track tooth riding up on the roller were observed. The result of this was increased wear of track teeth. As a result, the testers considered using a gearbox with new gear ratios and reduced drive sprockets a bad idea. In addition to the aforementioned drawbacks, putting a new type of gearbox into production would reduce parts commonality. The mass of the tanks also remained the same, so there was no sense in using a new gearbox.

A T-34-85M tank climbs a slope.

Special mobility trials also showed that the modernized tanks were no worse than the production vehicle. Both tanks could climb a 30 degree slope. A steeper hill could not be climbed due to the high degree of wear on the engines. The tanks could also drive at a 15-25 degree tilt. Towing trials were also completed successfully. No decrease in reliability was observed with the exception of accelerated wear on track teeth due to an unfortunate design of the drive sprockets.

The idea with reduced diameter drive sprockets proved poor. Track teeth showed a high degree of wear due to running up on the drive sprocket rollers.

The changes to the fuel system on the second variant of the T-34-85M were met with a mixed reaction. The commission did not deny the positive effects of moving the fuel tanks to the rear, but there were also drawbacks. The biggest drawback was that the fuel tanks got in the way of servicing the transmission. Filling the gearbox with oil also became harder. The experimental transmission had to be adjusted frequently during trials, which balanced the increase in safety with a maintenance headache. The fuel tanks could remain in place only if it could be guaranteed that the tank could drive for 500 km without needing adjustments to the transmission. The testers also didn't like the increased complexity of the tank's sides, suggesting that the side near the fuel tanks also needs to be sloped. In general, the commission ruled that it doesn't make much sense to move the fuel tanks here, since the drawbacks cancelled out the benefits.

The rear fuel tanks were criticized because they made servicing the transmission more difficult.

There were also questions about the modernized armour. The commission considered the 15 mm floor more vulnerable against enemy anti-tank mines and fougasses. The armouring of the hull DT machine gun was also considered not particularly good. The increased weld seam perimeter weakened a larger area of the front armour. The suggested solution was installing a fixed machine gun without a large bulge like on the KV-85, T-44, and IS tanks. There were also issues with the balancing mechanism on the new driver's hatch. The report claimed it was unsuitable for use.

T-34-85M tank driving at a tilt.

The commission rejected both variants of the T-34-85M as a result of these trials, but spoke positively about the increase in hull and turret armour. The NIBT proving grounds suggested a third variant of modernization. The front of the hull and turret were thickened as with the first two, the front floor armour remained 20 mm thick, but the hull MG was replaced with a fixed one.

Half-measure

The mixed results of trials didn't mean that the modernization project would be abandoned. Correcting all of the drawbacks to match the testers' requirements would not take too long. Trials of the T-44 were also not going very well. The T-34-85's replacement was going to be late, which caused a turbulent discussion between the NKTP and GBTU, which suggested that the T-34-85M should be put into production instead of the T-44.

The T-34-85M was used for penetration testing after mobility trials were finished.

While the discussion around the T-34-85M raged on, work continued. Trials didn't just involve driving. Testers needed to find out what the armour was good for in practice. Usually specially made test hulls were used for this task, but not in this case. The first variant of the T-34-85M was used for testing. Since it was rejected in its existing form, it was no longer needed. The armament, engine, gearbox, final drives, and a portion of the road wheels were removed before trials. An inspection before trials confirmed the criticism of the machine gun cowl issued by the NIBT. It turned out that there were rather substantial cracks around the machine gun mount. Cracks were also found in the area of the tow hooks and later in the sides of the hull.

Results of shooting at the upper front plate.

Like the T-44 hull, the T-34-85M was not subjected to the 7.5 cm Pak 40, but to the 75 mm KwK 42 L/42 used on the

Panther tank. The 88 mm Pak 43 L/71 used on the

Nashorn tank destroyer was also used against the prototype. Of course, the armour wasn't designed to deal with these weapons, but after the Red Army encountered these new guns at the Battle of Kursk it was no surprise that the GBTU wanted to understand how the T-34-85M's armour stood up to them. Interestingly enough, the German shells didn't always perform as advertised. Some of them had a muzzle velocity of just 860 m/s. This was due to using gunpowder from different production years. The guns were fired at a range of 100 meters.

An 88 mm HE shell blew off the machine gun cowl.

The results of the trials were quite mixed even if you keep in mind that the armour was designed to resist a completely different gun. Some publications claim that the Panther was capable of penetrating the T-34-85M's front armour from 650 meters, but that was not the case. Even the calculated limit of penetration was 720 m, but there were some nuances. The quality of the armour and weld seams was considered insufficient. The machine gun cowl was blown off when hit with an 88 mm HE shell. Impacts from 88 mm AP shells (most of which were fired at the upper front plate) widened the cracks. The increased thickness of the upper front plate was just a half-measure, as the lower front plate remained the same.

The quality of welding seams was criticized.

Trials showed that the range at which the Panther could penetrate the upper front plate of the tank was reduced from 1450 m to 720 m. The distance for the 88 mm Pak 43 L/71 was reduced from 4275 m to 1800 m. The advantages of the tank with improved armour were negligible. Even this increased armour wouldn't allow it to fight the Panther as an equal. The front armour would have to be thickened to 90 mm, both the upper and lower plates. The commission also requested that the quality of welding be improved and the commander's cupola reworked to improve protection. The issue of improving the quality of armour was also raised to the People's Commissariat of Ferrous Metals.

The T-34-85M did not go into production, but a T-34-85 turret with reinforced armour went into production in August of 1944. The tank's armour was improved after all, albeit partially.

Attempts to defend the T-34-85M were made even after Stalin signed GKO decree #6209s "On organization of T-44 medium tanks at NKTP factories #75 and #264". The tank's fate was already sealed. It was impossible to increase the front armour to 90 mm without significantly increasing the tank's weight and overloading the chassis. The first T-44 prototype with 90 mm of armour was already available by the summer of 1944. However, it is incorrect to say that this the T-34-85M was a waste of time even though it only remained a prototype. In a way, it went into production in August of 1944, although not under the index T-34-85M. The new turret with 90 mm thick armour was taken to be installed on the "classic" tank. This increase had nearly no effect on the tank's weight, but significantly improved the protection of the turret against enemy shells. As practice showed, most hits were aimed at the turret, and so increasing its armour was the right call.

When reading this, it seemed the whole T-34/85M idea suffered from mission bloat during its lifetime. The design was not perfect but seemed to do reasonably well (from my reading of this article) and would have been well-protected against the ubiquitous Pak40 AT gun, but then there came an obsession with making a tank with frontal hull protection against both the Kwk42 and Kwk43 guns, both of which were far more rarely encountered. The perfect became the obstacle to the good enough.

ReplyDeleteAnd why wasn't 60 mm good enough? That would calculate to be equivalent 150 mm of vertical armor, and the Pak40 would certainly struggle with that (even considering overmatching). And even if going to 75 mm would make the T-34/85M impervious to the Pak40 on a hit to the hull, it could still be penetrated by a hit by the Pak40 to the flatter regions of the 90 mm turret front. Why try to make a tank impervious to one a hit on one of its frontal surfaces if a hit on another surface by the same weapon can destroy it? If weight savings was such a big deal, 60 mm on the front would be a good compromise and give the front hull and the front turret equally good resistance, which is what I'd think you'd want. It is quite impossible to design the "unstoppable tank" so don't try. The biggest problem with the T-34/85 was that it's frontal hull armor had become weaker than its improved turret armor (you posted a report by the 2nd Guards Tank Army on cause of gunfire losses a while back, which showed that more T-34s were being lost to hits on the hull than the turret, which confirms this) and thus even going to 60 mm of armor would help that situation markedly. The biggest issue of the Red Army in the later war years was the manpower situation, not hardware availability, and this change might have saved many tankers' lives.

The biggest drawback insofar as I could see, would be the thinner armor on the bottom (and subsequent loss from mines). As mines were a common cause of tank loss, that's justified; but I recall more tanks were still lost to AT gunfire than mines, so the changes would still be beneficial. The additional weight and corresponding potential suspension issues are concerns, for sure, but the question to me is "would you rather have to a bit more maintenance on your tanks, or would you rather *lose* both tanks (and crews) in combat? As long as the additional maintenance issues are modest, the additional armor would be justified.

I think they had mistakenly assumed the KwK42/43 would become the standard, much as how the PaK40 and KwK40 near-totally replaced earlier weapons of their class in production.

DeleteT-43 died for the same exact reason - the armor was good against the 75mm L/48 but was just as worthless as the regular T-34 against the long guns.

I'm not sure the Soviets realized what a struggle the Germans would have getting the better guns out in number. The L/48 ended up being far and away the most common gun until the end of the war as you say.

The thing is, Tokyo, the Soviets did not apply the same reasoning to the IS-2 and its development. The IS-2 model 1944 was not invulnerable to the Pak40 at point-blank range at all frontal surfaces (though it was close). The IS-2 was still vulnerable to the Kwk36 and the Kwk42 at short ranges, and to the Kwk43 still further out. Yet the IS-2's armor deficiencies didn't stop it from being built; its 'imperfect' armor did allow it to engage both Tiger Is and Panthers in relative safety at 1000 meters and even take on King Tigers at 1500 meters with about the same degree of safety. Not perfect (which is why the IS-3 and IS-4 were designed and built) but deemed good enough.

DeleteIf you're ok with that for your heavy tank, why insist that your medium tank be able to withstand a hit from a gun like the Kwk42 and the same or shorter ranges that your heavy tank cannot? That does not compute. A T-34/85M with even 60 mm of hull armor would be able to resist hits from anything with a Pak40 gun--PzIVs, Marders, Hetzers, JadgpzIVs, StugIIIs, etc) at at least 500 meters or longer while being able to destroy all of these with its own gun. That's a huge advantage for the T-34.

As for fighting the Panther (only about 300 of which were on the whole Eastern Front in mid-1944) even having impenetrable armor on the T-34/85M does not help the fact its 85 mm would struggle against many of the Panther's frontal surfaces. A T-34/85M with even 60 mm of hull armor would have about equivalent turret and hull protection, and it would resist the Kwk42 at maybe 1200 meters or so, but would still be at a disadvantage in a frontal-head-to-head meeting (the T-34's 85 mm can get through some places on the Panther's frontal armor at c. 1000 meters but they're relatively small and hard to target where the Kwk42 would like penetrate anywhere it hit the T-34 at that range). The T-34's biggest advantage is that the Panther's side armor was weak even against highly oblique hits from the 76.2 mm gun on T-34/76s, let alone the 85 mm.

But to 'fix' the T-34/85 vs Panther, problem, you need a new tank with a D-10 or better. That's what later T-44 versions and T-54 were all about. To me that's not a argument against the T-34/85M fix.

I wholly agree, and personally think the ditching of the T-43 (with an 85mm fitted in it, of course) and T-34/85M were bad moves.

DeleteAt least they finally got something nice with the T-44/100 and then T-54.

The straightened upper hull on the IS-2 was a response to the appearance of the KwK 42, there wasn't an easy upgrade that could be made to the T-34-85 like that. I agree that the 60 mm front would have been useful, but like Tokyo said the Red Army overreacted and assumed that 75 and 88 mm guns with 1000+ m/s of muzzle velocity were going to be standard going forward.

DeleteIt's always interesting, given that modern tanks have dispensed with hull MGs entirely, to see how nearly all the parties to WW2 clung onto them. There seems to have been a strong strain of thought amongst procurement officers all over the world (presumably reflected in the opinions of the tankers themselves) that the things were useful - even to the point of introducing half-measures like fixed MGs.

ReplyDeleteI'd love to know what the reason is here.

If I remember from the T26's development, it was for suppressive fire and immediate reaction shots against ambushes when the turret wasn't aimed on target.

DeleteOrdnance wanted to ditch the hull MG on T26 and fit ammo stowage racks there (to meet the 70 round AGF stowage requirement), but AGF refusing to budge on the hull MG and 70 round requirement meant sacrifices elsewhere - the single-plane gun stabilizer was deleted as a result to free up space for ammo.

Well it was the wartime experiences of their limited utility in practical combat that caused their abandonment. Plus often the bow gunner doubled as radio operator, which role became superfluous once the electronics were refined into more compact and less temperamental designs that the commander could handle himself without undue distraction.

DeleteThe explosive increase in gun power and due need to prune any unnecessary perforations that weakened the main armour belt no doubt also contributed.

Tellingly essentially all the next-gen designs in the pipeline at the end of the war had ditched the bow MG or at least reduced it to the vestigial minimum of the T-44 (though that setup had already been used in some interwar tanks). The only holdout was the Americans, still in thrall of what some historians archly call "the cult of the machine gun" - witness the peak "more dakka" lunacy of the M2 Light with its whopping 5 bullet hoses - who stubbornly clung onto that archaic accessory until the introduction of the M48 in '52.

That's extremely interesting entry for me! Some time ago I created thesis that in T-34 usage vertical rear armour can be useless. I created this thesis, because if we use vertical rear armour instead sloped armour, in this case we create extra space above gearbox- probably useless space, because if we mount something above gearbox, in this case decrease accessiblity into gearbox and steering system. This entry proved my thesis- extra fuel tanks located above gearbox decrease accessibility.

ReplyDelete