The British found themselves in an undesirable situation in North Africa by 1941. Matilda and Valentine infantry tanks were quite modern and often vulnerable only to 88 mm AA guns, but cruiser tanks did not measure up to their opponents. Even the Crusader, the most modern vehicle of its class, was armed with the same 2-pounder gun as its predecessors. The armour was a little bit thicker than the last generation, but still only resisted the 3.7 cm Pak from long ranges. These tanks were outmatched when German Pz.Kpfw.III and Pz.Kpfw.IV tanks hit the battlefield in 1941. With the British “heavy cruisers” still in early stages of development, salvation came from the Americans with their Medium Tank M3.

Picky guests

The British first asked the Americans for tanks in the summer of 1940, after a large percentage of the British tank force was lost in France. The initial proposal was to build British tanks under license at American factories. This offer was rejected. The British would receive the same tanks as the American army used. However, the USA still had no modern medium tanks, and the British still had some influence on their creation. One of the aspects was the volume of production.

|

| Assembly of the Medium Tank M3. |

The initial plan was to produce the Medium Tank M3 in limited volumes, a few hundred vehicles at most, and then move on to a superior model. However, the British wanted as many tanks as possible, as soon as possible. A contract for 685 tanks was signed with Baldwin Locomotive Works, 500 tanks with Pullman Standard Manufacturing Company and Pressed Steel Car Company, and 100 tanks with Lima Locomotive. The British ordered almost as many tanks as the Americans did. Production plans called for assembly of 8 tanks for the American army and 6.5 tanks for the British per day by the end of 1940.

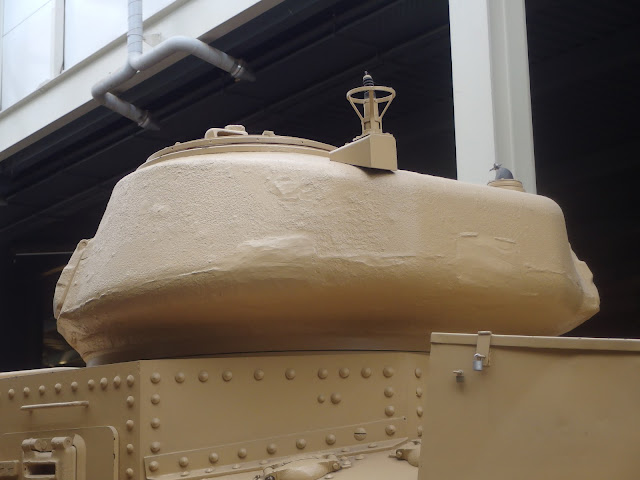

The British also influenced the tank’s design. L. Carr, a British engineer with a lot of influence in American industry, designed a new cast turret for the Medium Tank M3. It was larger than the American one and had a large bustle that could house a radio set. Instead of a machine gun cupola, a two flap hatch with a periscope was installed. This was a common solution in British practice. Tanks of this type were nicknamed “General Grant” after Ulysses S. Grant, a Union General in the American Civil War. Tanks with the American turret were nicknamed General Lee after Grant’s enemy, Confederate General Robert E. Lee.

|

| Grant (left) and Lee (right) tanks had different turrets. |

The first Medium Tanks M3 arrived at the proving grounds of the Department of Tank Design in Farnborough in late October of 1941. The tanks were classified as cruisers. The nicknames were not yet in use at that time and the documents simply called it “American M3 medium tank”. The indexes Lee I and Grant I came into use by November, but the old name was still used in many reports.

When comparing the reliability of American and British tanks, historians often mention that the former were much more reliable, but rarely go into details. As British specialists soon discovered, nothing was this simple. Their “General Lee” was suffering serious defects by November 1st: the engine was misfiring and one suspension spring broke. Various fluids leaked, including oil and hydraulic fluid, which could not be replaced easily. The British also complained that the air filters were hard to service. Since the radio was not yet installed on the tank, there were no more trials that could be performed. The tank stood idle awaiting parts.

|

| Unlike the American turret, the Grant had a radio in the turret bustle. |

A new spring was installed only on November 9th. Testers noted that the suspension springs were overloaded. The uneven weight distribution of the tank negatively affected not only the reliability of the tank, but also made loading it onto a trailer difficult. The tank was still plagued by defects. The voltage regulator burned out and several oil hoses burst, immobilizing it once again.

These issues repeated themselves on another Lee next week. Proving grounds staff had to disassemble the engine and clean fouling from the sparkplugs. Defects in oil system valves were discovered. Tanks would break down after only several miles of driving. One Grant lost all of its hydraulic fluid, after which the pump became useless. A pump was removed from the broken Lee for installation on the Grant filled with an ersatz hydraulic fluid, but this pump broke after only 4 miles of driving.

|

| A Lee tank on a Diamond trailer. It was not easy to load this tank due to its offset center of gravity. |

The proving grounds workshop managed to return one tank to service by November 15th by replacing the oil hoses with British made ones. The tank went through short trials, climbing up a 22°33’ slope (the tank could not climb a steeper one due to loss of traction) in first gear. An attempt to climb an 18°55’ slope in second gear failed. The average speed on the 3-5 km long cross-country drive was 15.6 mph (25 kph).

Testers noted that the left front suspension bogey was overloaded. The tank still exhibited mechanical issues: the engine squealed (the source was never discovered) and stalled under heavy load. Oil expenditure was exceptionally high.

Engine troubles worsened by November 22nd. The engine worked unevenly and often backfired. It was disassembled and proving grounds technicians found fouling on the sparkplugs. Some were even covered in oil. The sparkplugs had to be removed and cleaned again. To do this, technicians had to remove the engine deck and floor plates, which was a laborious task. The proving grounds staff had to get in touch with the Wright company to figure out these faults. The starter relay and ignition coil mounts also had to be fixed, as they fell off due to poor welding.

|

| Workers install an R-975 engine in a Medium Tank M3. The engine’s lifespan was low and the installation process was difficult. |

Trials of the General Lee continued until December 5th when the engine began to malfunction again and lost power. Trials had to be stopped until a new engine could be delivered. By that time the tank drove for 936 miles (1506 km) and the engine worked for 109 hours. Disassembly showed that it was heavily worn. The piston rings were sent to the USA for analysis. The answer arrived shortly and offered no solutions. Wear of this magnitude was to be expected and was not caused by faulty assembly.

Second breath

A new engine arrived by December 13th. Proving grounds staff recorded that the installation was quite difficult. It took three man days to remove the old engine, three more to transfer all of the accessories to the new one (the Americans sent no spares), and four to install the new engine. A gantry crane with a clearance of 312 cm was needed for this procedure.

The engine idled for 5 hours between December 13th and January 3rd. The tank also drove for 300 miles (482 km). Testers noted that the new engine was more powerful, but a repeat of the slope trials showed that the results were the same. The rest of the trials were not repeated. Fuel economy was calculated to be 60 gallons per 40 miles of cross country driving (428 L per 100 km). Issues with the fuel system persisted and the engine still stalled when driving in difficult conditions.

The tank then went through vertical obstacle trials. It failed to climb a 24 inch (61 cm) and a 19 inch (48 cm) tall wall. The drive sprocket passed above the obstacle, the front road wheel pressed up against it, and the track slipped helplessly. Testers blamed the location of the front drive wheel.

|

| Results of the vertical obstacle trial. The front bogey pressed up against the obstacle and the track slipped. The General Lee could be stopped by a relatively low wall. |

An accident took place during cross country driving trials. One track slipped into a rut and the tank flipped over. Attempts to flip the tank back using a Scammel transporter were fruitless. The tank driver decided to start up the engine to assist. This worked, but with a side effect: when the tank was upright again the engine backfired, igniting spilled gasoline.

The fire was put out using an external fire extinguisher. The tank’s driver noted that the internal fire suppression system was useless. He could not reach the switch located in the fighting compartment from his station, and in combat it would likely be blocked by the crew’s belongings. The fire was put out before the tank or the engine were damaged, but the British still decided to install a better fuel system. The faulty voltage regulator didn’t help with fire safety. The second fire extinguisher was used up when the wiring in the engine reached red-hot temperatures.

|

| A Grant tank on a trailer. |

Another mistake was made on January 17th. The testers left the tank in an unheated garage when they left for the weekend. Many defects were discovered upon their return. The maximum oil pressure fell, the engine operating hours counter and engine governor broke. Another leak formed in the hydraulics system. The tank was returned to service by January 19th, but another issue was detected then: significant track wear. The tracks were replaced by the end of the month, but this wasted several days. Proving grounds technicians complained that they lacked proper tools to service the tank. In total, by January 19th the tank drove for 1848 miles (2974 km), half on roads and half cross-country. In this time the tank developed 12 serious defects. 253 hours were spent on repairs. An inspection showed that six more suspension springs burst.

|

| A suspension bogey. The springs became the Achilles’ heel of the Medium Tank M3. They were later reinforced, but this did not fully resolve the suspension issues. |

Mobility trials were over and gunnery trials began. Issues cropped up here too. The effort required to traverse the turret was uneven, and so it was removed for inspection. It turned out that the turret ring was seriously worn after 2000 miles of driving. In part, this was caused by low quality of assembly. The British suggested the use of a turret ring under the turret basket, like on the TOG II. An auxiliary fuel system to combat stalling in difficult conditions was also recommended.

Lee and Grant tanks that were already issued to units were inspected by the end of February. Defects found in tanks under test were also found in these vehicles. Two engines needed replacement, another tank cracked its forward bogey mounts, many track links were broken, a replacement for American hydraulic fluid had to be developed due to constant leaks. Suspension spring failures were common.

A new tank on the M3 chassis arrived at the proving grounds in late March: the Ram I. This tank still had a number of defects characteristic of its predecessor, but it was much more interesting for the proving grounds. As of April 1942 the Lee rarely showed up in summary reports. Testers typically tried out various solutions for the tank’s many defects. An attempt was made to install British sparkplugs instead of American ones, but the difference was negligible. The tank was removed from trials after 113 hours of operation.

Universal weapon

While there were a lot of complaints about the chassis, the gun was a real leap forward for the British. In 1942 they were still working with the 6-pounder gun that only fired AP shot for regular tanks and the 3” howitzer that could fire HE and smoke reserved for close support tanks. Meanwhile, the 75 mm M2 gun on the Lee and Grant could effectively combat both tanks and enemy personnel.

|

| The French 75 mm Mle.1897 gun, an ancestor of the M2. Les Invalides museum. |

The British had information on the weapon’s ancestry by 1942. The ballistics of the gun were identical to those of American M1916 and M1917 cannons, which were in turn based on the French M1897 gun. Ammunition for these weapons was interchangeable. This was a major bonus, since there were plenty of British and French made shells cluttering up warehouses.

The British favourably compared the American gun with the German one installed in Pz.Kpfw.IV tanks and StuG III assault guns, recognizing that this was not just a support weapon. The M2 gun fired an effective AP shell that could defeat enemy tanks. The myth that the 37 mm gun was the Lee’s main weapon and the 75 mm gun was there for support is not confirmed by documents. The British wrote that the 75 mm gun was the main weapon, and the 37 mm gun was only to be used against rapidly moving targets like light tanks and armoured cars. This was not just a theoretical instruction. British crews preferred to load as much 75 mm ammunition as possible, even to the detriment of 37 mm ammunition.

|

| A Grant with an early 75 mm M2 gun, Bovington Tank Museum. This tank is equipped with WE210 tracks, usually used only on Lee, Grant, and Ram tanks. |

Since the guns had a very long family tree, there was quite a variety of ammunition available. American M61 APCBC-T shot with a muzzle velocity of 1850 fps (564 m/s) penetrated up to 89 mm of armour at normal, which allowed it to deal with any German tank of the era. There was also a semi-AP M72 shell available. This shell penetrated a 50 mm thick side of a Valentine tank at a range of 1400 yards (1280 m) in trials.

Calculated performance of M61 shot fired from the M2 gun according to British criteria (50% chance of perforation):

|

Range (yards) |

Penetration (mm) |

||

|

At normal |

At 20° |

At 30° |

|

|

0 |

89 |

79 |

66 |

|

200 |

86 |

73.5 |

63.5 |

|

400 |

82.5 |

71 |

61 |

|

600 |

79 |

68.5 |

58.5 |

|

800 |

76 |

66 |

56 |

|

1000 |

73.5 |

63.5 |

54.5 |

Older ammunition was also available. The Mk.IT AP shell could penetrate up to 60 mm of armour at 30 degrees at 600 yards. Semi-AP could penetrate up to 51 mm of armour at 30 degrees from 100 yards. There was also other ammunition that Lulworth proving grounds had no data on. Testers assumed that it was obsolete. Several of these rounds were fired at the proving grounds. Testers complained about the poor design of the ammunition and short-burning tracers. They recommended using old model AP rounds for training only and disposing of the semi-AP, as there was no use for them. It was unsafe to fire them from a tank due to the amount of fumes produced.

|

| A Grant tank with a later model of the M2 gun, IWM Duxford. The counterweight means that the gun is equipped with a stabilizer. This tank has late type T54E1 tracks. |

The variety of HE shells was even greater. Like with old semi-AP, most of them were unsafe to use in tank guns. Testers recommended using American M46 or M47 shells. The M46 could be fired at a range of up to 4200 yards, but the gun had to be elevated so high at even 1800 yards that the gunner could no longer see the target in his sights. The British also knew about a new M48 shell, but had no information on it.

There were also Mk.I and Mk.II smoke shells available, based on the design used in the 3” howitzer. These shells were not as effective as German ones. Due to limited gun elevation, the maximum range with these shells was just 1500 yards (1371 m).

|

| Ammunition developed for the screw breech of the French gun did not work very reliably with a semiautomatic sliding breech. Les Invalides museum. |

The excellent gun was not without drawbacks. The location of the gun in the sponson not only limited its traverse to 28 degrees (14 to each side), but made the commander’s job harder. The commander could not see what the gun crew was doing and it was difficult to talk to the gunner through the intercom if the engine was running. It was impossible to fire with the engine shut off as the electric firing mechanism needed the generator, but even the auxiliary motor was too loud for the gunner to hear orders over it. The engine was also necessary to clear the fighting compartment of gun fumes. The concentration of fumes at the loader’s station exceeded the allowed limit even at an idling speed of 1000 RPM.

Firing on the move was not recommended. The aiming mechanisms were not reliable enough to aim quickly and the tank did not carry enough 75 mm ammunition to waste it. Additionally, the tank violently swayed side to side when driving in mud or on difficult terrain. Grousers helped little, as they quickly became packed with mud.

Sights were another drawback. The British did not like either the telescopic nor the periscopic sights. The M1 periscope was badly designed. Its casing let through dust and moisture, it was easy to break while cleaning, and had a tendency to burst when the gun was fired. It was hard to zero in the sight, but also pointless, as there was no way to fix the setting. Targets at the proving grounds could not be seen through it at a range of 1000 yards (914 m), while reports from the front indicated that tanks often fired at distances twice that far.

|

| An HE shell for the French 75 mm gun, Les Invalides museum. It was possible to fire these from a Lee tank, but not safe. |

The M21 telescopic sight also left much to be desired. Lack of magnification meant that it was impossible to use it for firing at long range. Light transmission was poor and the markings were so thick that they could completely obscure the target. The sight showed awful results at trials. The gunner could not see a moving person or a 4 foot square on a black background from 950-1000 yards (868-914 meters). Furthermore, markings were only present for a few types of ammunition: M61, M72, and supercharged M48, the latter of which was not available at the proving grounds. The range for all other types had to be estimated.

The driver and commander’s observation devices were judged as adequate. Aside from a dead zone behind the tank, visibility was good. Testers found a tendency of the prisms to distort the image if it was not viewed at a right angle.

Overall, the M2 gun was received positively. It was considered a satisfactory measure until the 6-pounder and 17-pounder could be fielded. Testers noted that a lack of appropriate ammunition and poor sights reduced the effectiveness of shooting.

The 37 mm gun was also tested. It turned out that the gun was badly unbalanced, which was corrected with a counterweight. The spent brass bag had to be replaced, as the American one was deemed too flimsy. The elevation mechanism allowed the gunner to aim with either a shoulder stock or a flywheel, which the British liked. However, this mount gave bad depression: only 4°50’ compared to the 7° claimed in the manual.

|

| The British considered the fixed machine guns in the upper front plate useless. |

The British also liked the coaxial gun, but with the caveat that the length of the ammunition belts and size of the spent brass bag were insufficient. The fixed machine guns were entirely useless and needed to be removed. The Americans seemed to be in agreement, as the Medium Tank M4 quickly lost them. The machine gun in the commander’s cupola was not so well received. The British preferred their own observation devices and the PLM mounting for the machine gun.

On May 30th, 1942, a General Lee tank with a gyroscopic stabilizer was tested. The gun was fired at targets 500 yards away. Due to the unpredictable nature of the Logansport turret traverse mechanism, only hand traverse was used. Firing forward while driving at 8 and 12 mph (13 and 19 kph) an untrained gunner’s hit rate was 7 percentage points higher with the stabilizer on than without. Benefits for experienced gunners increased to 11 and 22 percentage points. Testers noted that the rate of fire also increases when the gun is pointed forward.

|

| Results of firing with a stabilizer (right) and without (left). The rate of hits increased from 59 to 72.5%, the rate of fire increased from 7 to 9.2 RPM. |

The stabilizer was not very useful if the gun was aimed away from the direction of movement of the tank, only a few percentage points gain was recorded. One experienced gunner even got a worse result when using a stabilizer. Firing broadside was even worse. The effectiveness of the stabilizer also depended on terrain. For optimal results, the tank had to drive forward uphill at an even pace.

As the General Sherman with a 75 mm gun in a turret was already known to the British, the 75 mm gun on the Lee did not go through trials.

|

| General Lee tanks in the UK, 1942. |

As a result of the trials testers at Lulworth composed a list of 77 design defects that had to be corrected. Some of them were corrected at British factories after the vehicles were delivered, some were tackled by the Americans. The tank was deemed fit for service.

Trials showed that the American tank was far from perfection. It had some advantages over British vehicles, but American tank designers had a long way to be before they could offer a truly high quality tank to the Allies.

Sources:

- Richard P. Hunnicutt. Sherman: A History of the American Medium Tank — Echo Point Books & Media, 2015

- Documents from the archive of the Canadian Military Headquarters, London (1939–1947), RG 24 C 2

This article was originally published on Warspot.net

No comments:

Post a Comment